FRIGIPAN IS ONE OF A FEW PANEL MANUFACTURERS

MANUFACTURERS OF TONGUE AND GROOVE (MALE – FEMALE) AND HARDBOARD BARRIER STRIP JOINTS FOR INSULATED PANELS.

JOINT SYSTEMS

Cold Room Joints: Ensuring Optimal Sealing and Efficiency

In the world of cold storage, every element of design plays a critical role in maintaining temperature control and ensuring the overall efficiency of the system. Among these key elements, the type of joint used in cold room construction is particularly important. High-quality joints contribute to the insulation of the cold room, preventing temperature fluctuations and minimizing energy consumption. Two popular options for cold room joints are tongue and groove (male-female) joints and hardboard barrier strip joints. Both have unique advantages depending on the specific requirements of the cold room.

The Importance of Cold Room Joints

The primary function of a cold room joint is to provide a secure, airtight seal between the insulated panels that form the walls, ceiling, and floor of the room. A well-designed joint prevents air leaks, which can compromise the cold room’s internal temperature and increase the strain on refrigeration systems. Efficient cold room joints also reduce energy costs by keeping the cooling system from overworking. This makes the selection of the right joint crucial for the longevity and performance of any cold room installation.

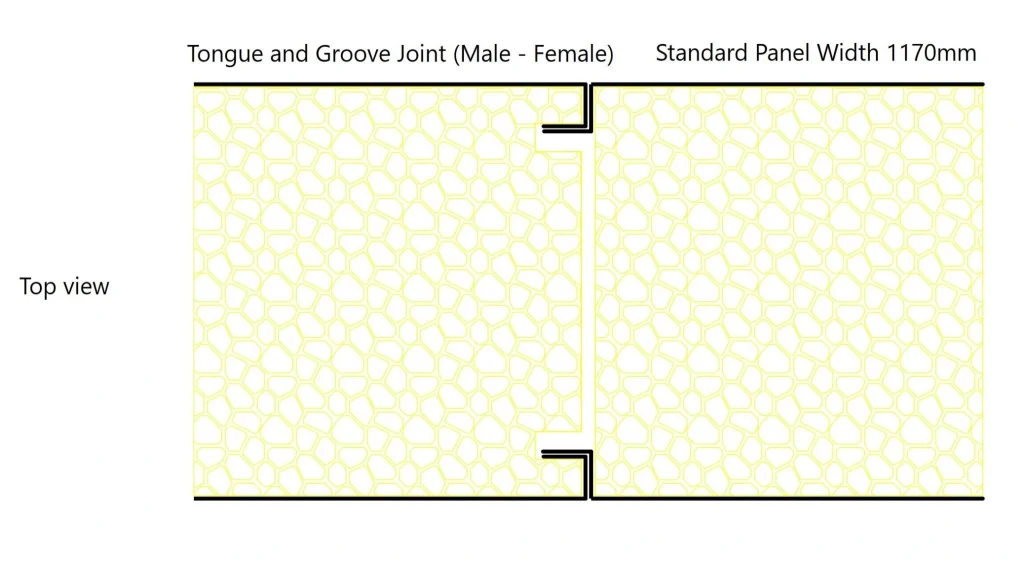

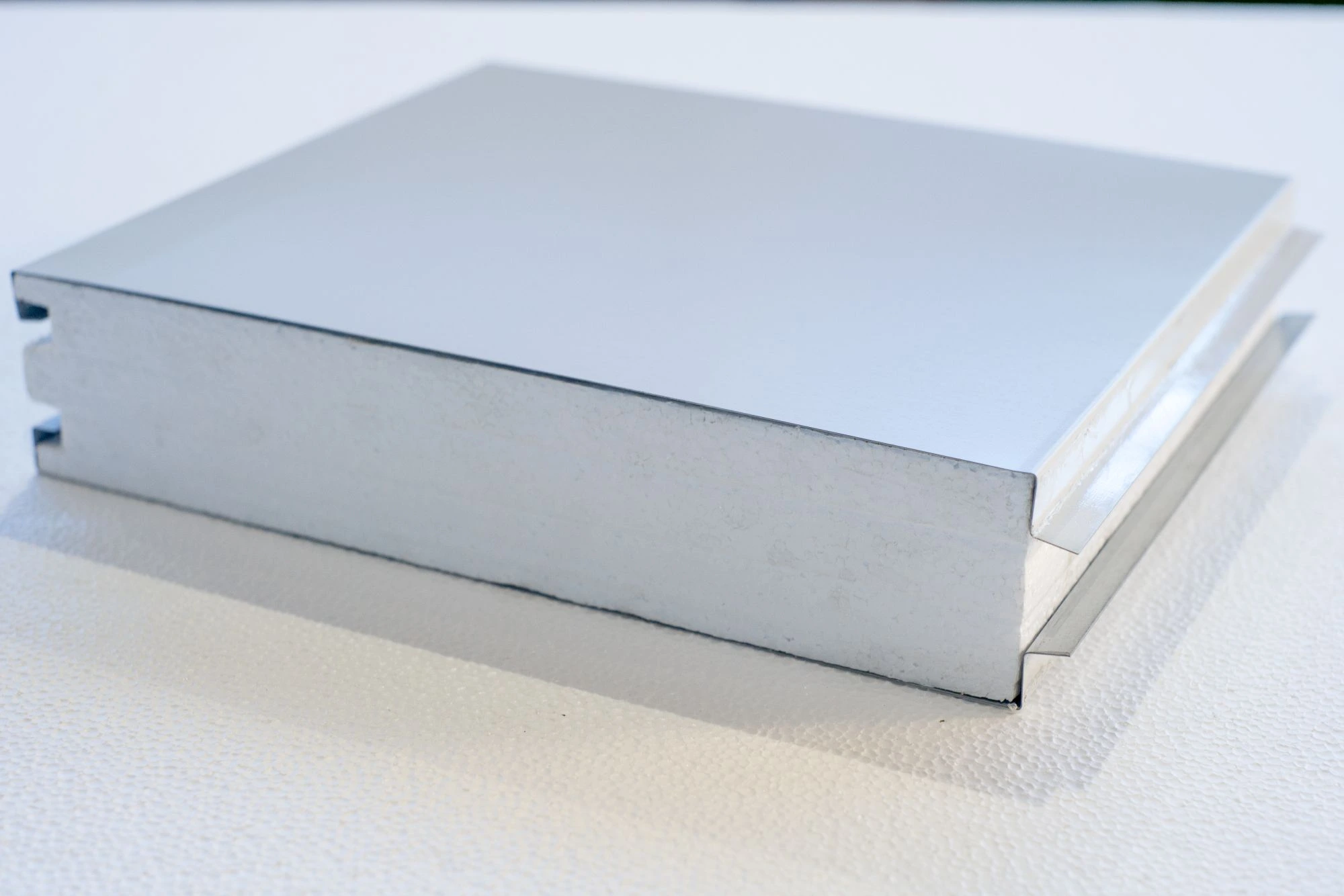

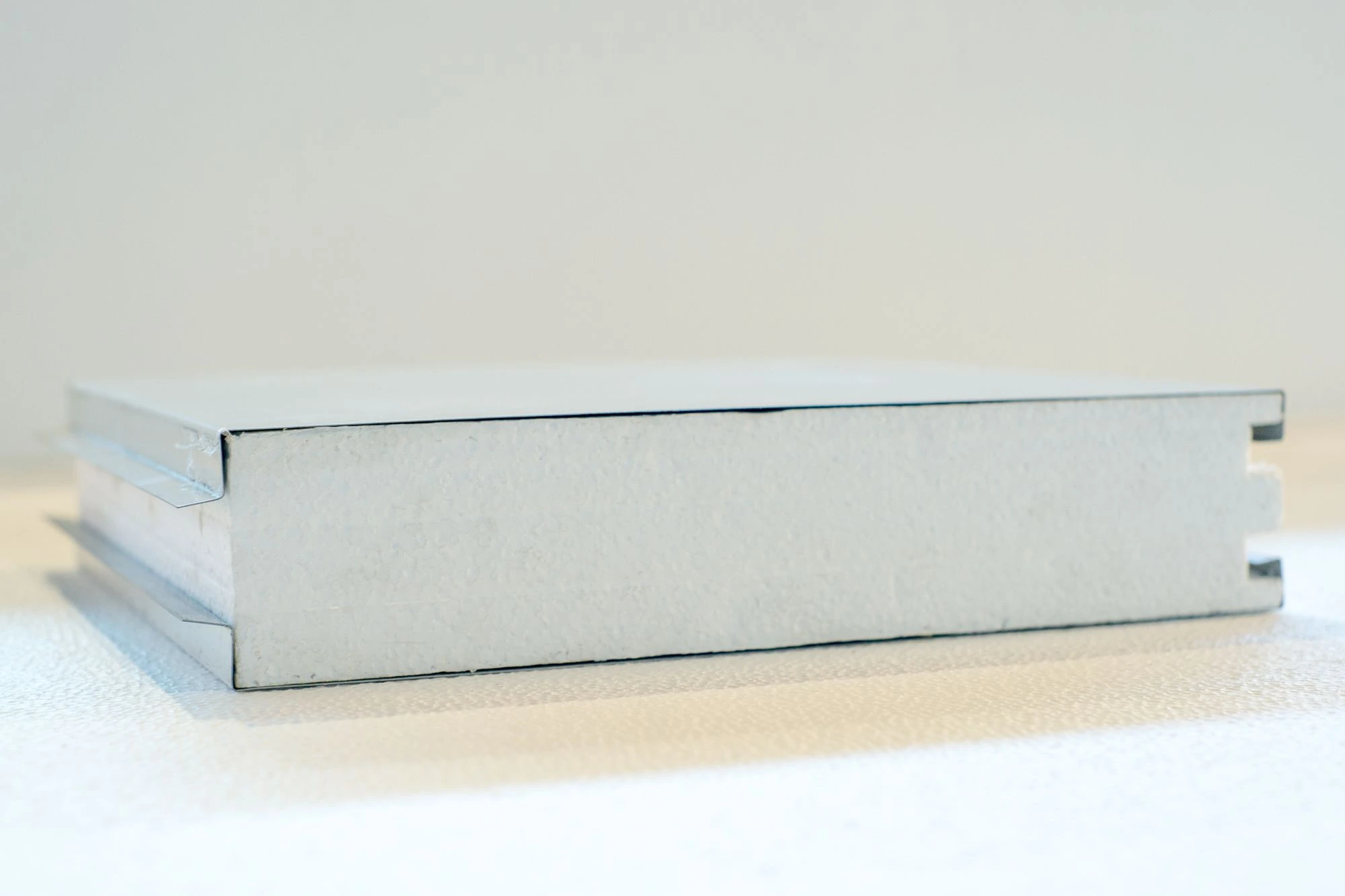

Tongue and Groove (Male-Female) Cold Room Joints

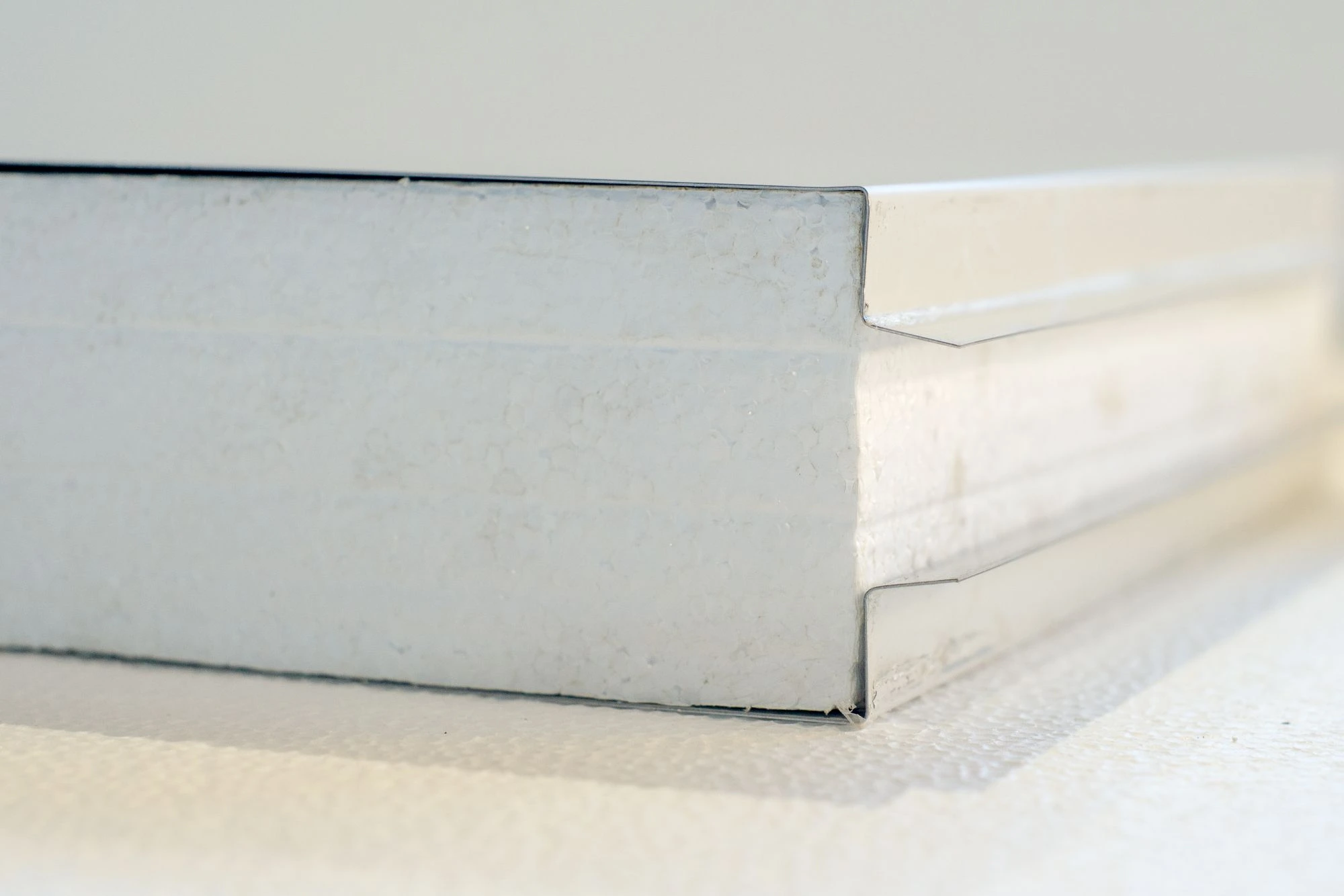

Tongue and groove joints, also known as male-female joints, are one of the most common choices for cold room construction. This system involves interlocking insulated panels, where one side of the panel (the “male” side) has a protruding edge that fits snugly into a corresponding recessed edge (the “female” side) on the adjacent panel. This design ensures a tight, seamless connection between panels, minimizing any gaps that could allow air to escape or warm air to enter.

One of the key benefits of tongue and groove joints is their ease of installation. The panels click together quickly and securely, which not only speeds up the construction process but also reduces labor costs. In addition, the interlocking design provides a stronger, more durable bond between the panels, enhancing the overall structural integrity of the cold room. These joints are particularly well-suited for commercial and industrial cold rooms that require long-term reliability and efficiency.

The precise fit of tongue and groove joints also helps to reduce the amount of sealant or adhesive needed, further streamlining the installation process. Because the panels are so closely connected, there is little risk of thermal bridging, a phenomenon where heat transfers through gaps in the insulation. This helps the cold room maintain a stable temperature, which is essential for preserving perishable goods and ensuring the cold room’s energy efficiency.

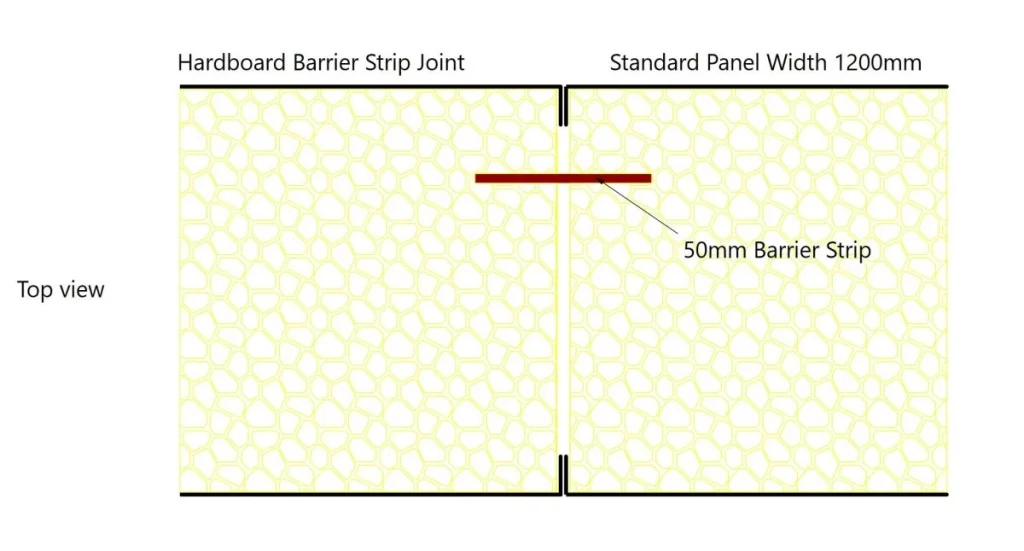

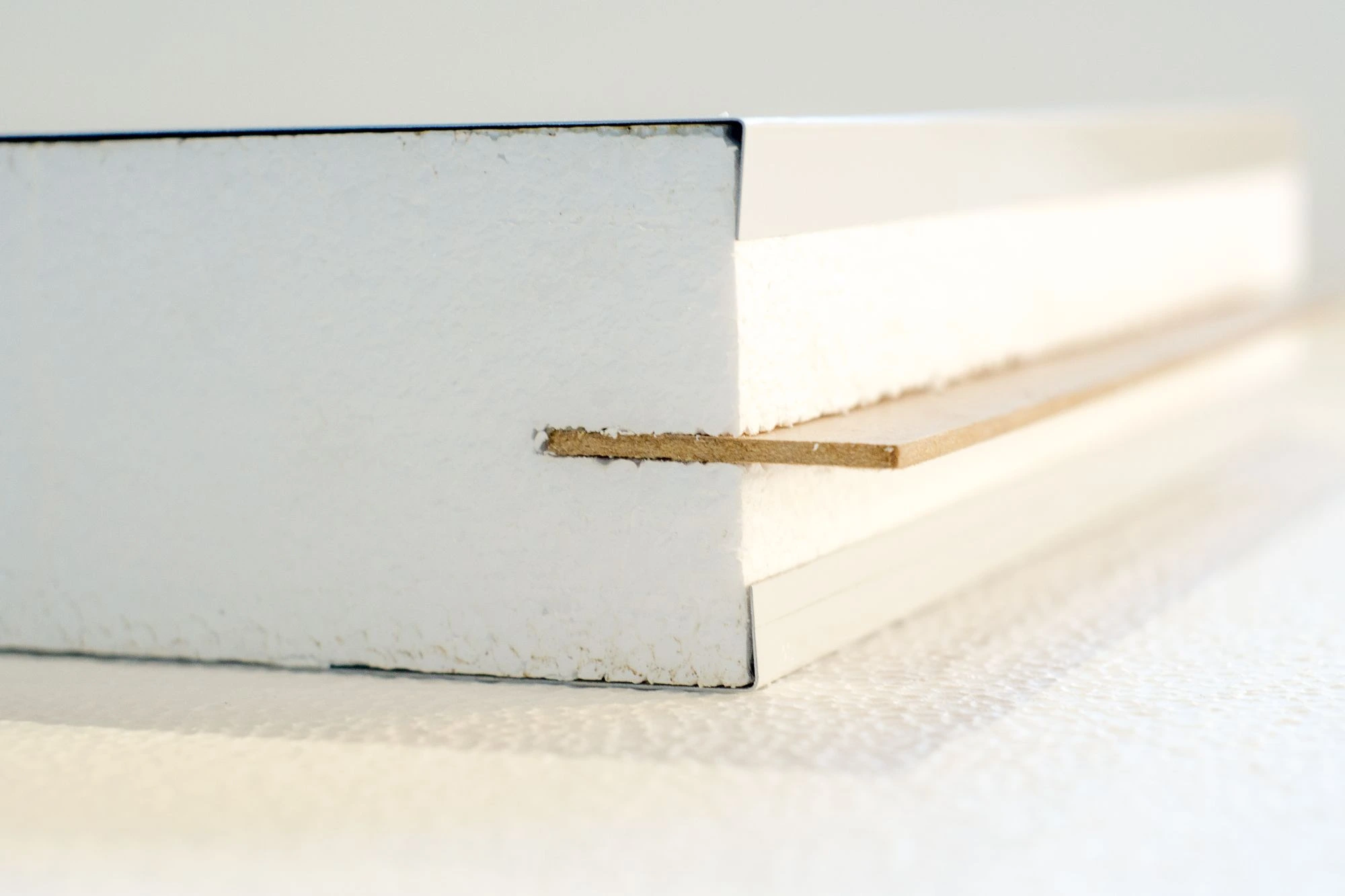

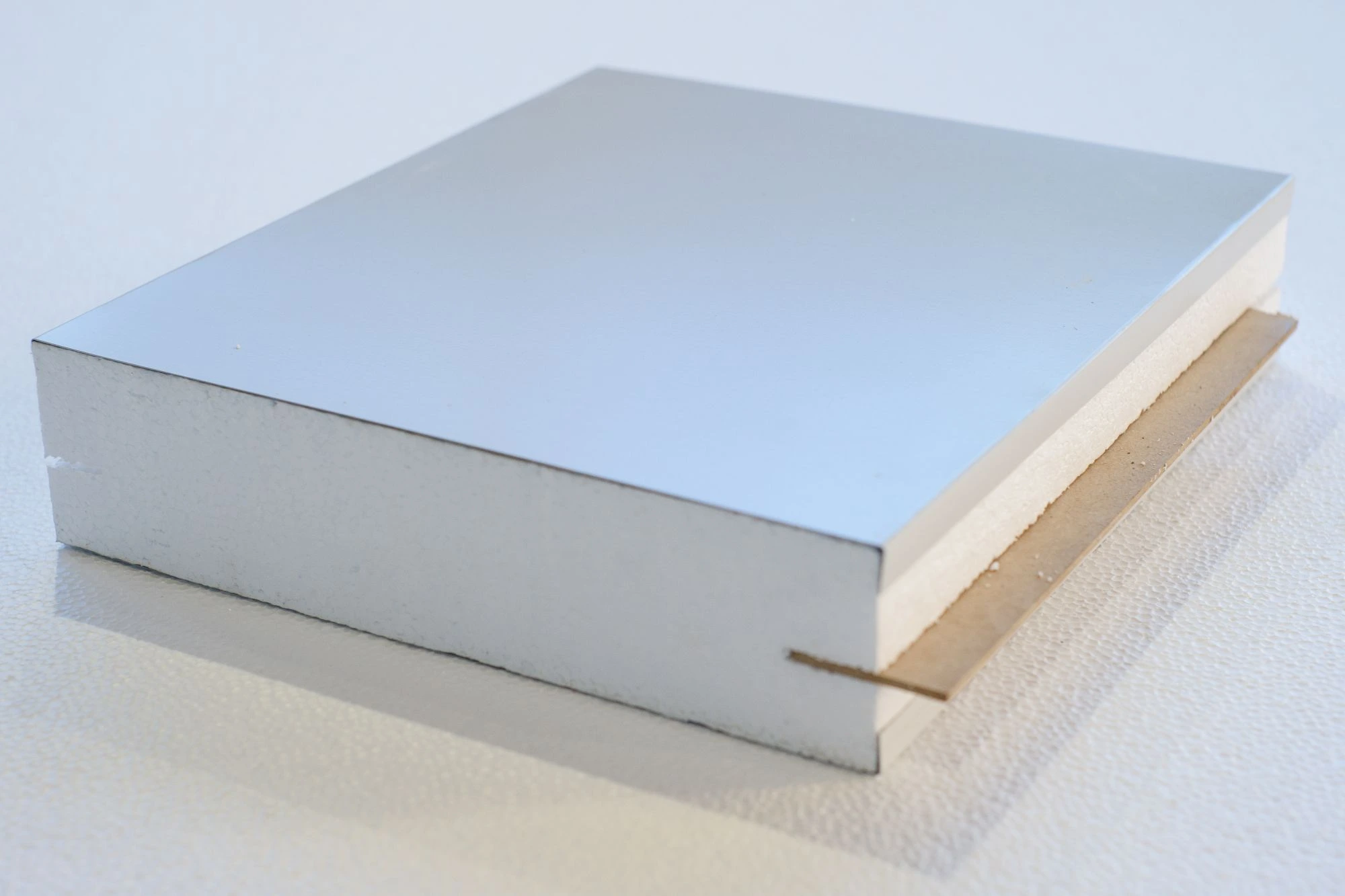

Hardboard Barrier Strip Joints

Another popular joint option is the hardboard barrier strip joint. Unlike the tongue and groove system, these joints utilize a hardboard strip that is placed between two insulated panels to create a seal. The barrier strip acts as a thermal and moisture-resistant layer, preventing cold air from escaping and reducing the risk of condensation forming between the panels. This method is ideal for cold rooms that operate in high-humidity environments or where temperature fluctuations are frequent.

Hardboard barrier strip joints are known for their durability and resistance to wear and tear. Over time, cold room joints can degrade due to constant exposure to extreme temperatures and moisture. The use of a hardboard strip reinforces the joint, providing an additional layer of protection against these elements. This can extend the lifespan of the cold room and reduce the need for maintenance or repairs.

While installation of hardboard barrier strip joints may take slightly longer than tongue and groove joints, the added protection they offer can be invaluable in certain applications. For example, cold rooms used for pharmaceutical storage or food processing may benefit from the extra layer of thermal resistance and the increased protection against moisture.

Choosing the Right Cold Room Joint for Your Project

Both tongue and groove (male-female) joints and hardboard barrier strip joints offer excellent sealing capabilities for cold rooms, but the right choice depends on the specific needs of your project. For applications where speed of installation and structural strength are priorities, tongue and groove joints may be the ideal solution. Their interlocking design not only ensures a tight fit but also makes the construction process more efficient. On the other hand, if you are building a cold room in a high-moisture environment or require extra insulation, hardboard barrier strip joints may be the better option.

Regardless of which joint system you choose, it is essential to ensure that the cold room is designed and installed by experienced professionals. A poorly sealed joint can lead to air leaks, increased energy consumption, and higher operating costs. Working with a trusted cold room specialist will ensure that your cold room is built to the highest standards, with joints that provide long-lasting performance.