7 Powerful Benefits of Sandwich Panels:

Sandwich Panels:

In modern construction, insulation, and refrigeration, sandwich panels have gained immense popularity due to their outstanding thermal insulation properties, durability, and strength. These versatile building materials have widespread use across various sectors, from cold storage to commercial buildings, industrial structures, and even residential applications. With their robust yet lightweight design, they provide efficient solutions for construction and insulation needs. In this blog, we’ll explore what sandwich panels are, their various uses, and the seven key benefits that make them indispensable in the modern building landscape.

What Are Sandwich Panels?

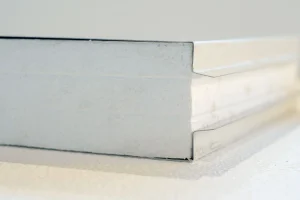

It is a composite material typically composed of three layers: two outer skins and an insulating core in between. The core material is the central component responsible for the insulation properties, while the outer layers serve to protect the core and provide structural strength. Sandwich panels can be used for walls, roofs, ceilings, and floors, making them highly versatile in building and insulation applications.

The outer skins are generally made from strong materials like steel, aluminium, fibreglass, or PVC, while the core material is often polyurethane (PUR), polystyrene (EPS), mineral wool (MW), or polyisocyanurate (PIR). These materials are selected based on their performance in terms of thermal resistance, fire resistance, and durability.

The layers are bonded together using advanced adhesives or mechanical methods, creating a highly efficient, strong, and lightweight building material. The “sandwich” structure helps deliver excellent thermal performance while also making the panels much lighter and easier to handle during installation compared to solid insulation materials.

What Are Sandwich Panels Used For?

They are used in a variety of applications across different industries. The unique combination of strength and insulation properties makes them an ideal solution for many building and insulation projects. Below are some of the most common uses:

1. Storage Facilities and Refrigeration Rooms:

The panels are extensively used in the construction of cold storage warehouses and refrigeration rooms. These applications require optimal thermal insulation to maintain specific temperatures, ensuring that goods like food, medicines, and chemicals are stored at the right temperature to prevent spoilage or degradation.

Sandwich panels help maintain energy-efficient cold environments by minimizing heat transfer from the outside to the inside of storage rooms. This reduces the energy consumption needed to keep the room cool and lowers operational costs.

- Agricultural Buildings:

The agricultural sector relies on sandwich panels for constructing barns, greenhouses, livestock buildings, and storage facilities. These buildings require a high degree of thermal insulation to protect the stored crops, animals, and equipment from temperature extremes. Sandwich panels help maintain stable temperatures, which is crucial for the health of livestock and the storage of perishable crops.

3. Industrial Buildings and Warehouses:

The construction of industrial buildings and warehouses often requires robust insulation that can withstand challenging environments. Sandwich panels offer both strength and insulation, making them an ideal choice for creating energy-efficient buildings.

Industrial buildings often experience extreme conditions, such as high humidity, extreme temperatures, and heavy-duty operations. Sandwich panels are designed to provide an optimal solution by preventing thermal bridging and ensuring a stable temperature inside, regardless of external conditions.

Furthermore, these panels allow for easy expansion of industrial spaces. Whether adding more storage areas or increasing the height of buildings, they can be integrated into the existing structure with ease.

4. Clean Rooms and Pharmaceutical Facilities:

In sectors like pharmaceutical manufacturing, laboratories, and healthcare, clean rooms are required to maintain stringent environmental conditions, including temperature and humidity control. Sandwich panels are used in these applications because of their ability to provide exceptional insulation while ensuring clean, sterile environments. The panels made with polyurethane or mineral wool cores are ideal for clean rooms due to their high thermal performance and fire resistance.

These panels also provide smooth surfaces that are easy to clean, helping maintain the necessary hygiene standards in pharmaceutical production and other critical environments.

5. Commercial Buildings

In the construction of commercial buildings, sandwich panels provide a fast and efficient way to build insulated walls and roofs, they are commonly used in shopping centres, showrooms, office buildings, and manufacturing facilities.

The materials can be finished with various coatings, offering both aesthetic appeal and functionality. Commercial buildings need to ensure energy efficiency and durability, and the panels help address both concerns by providing an excellent barrier against heat loss or gain.

6. Residential Applications

Although sandwich panels are more commonly used in commercial and industrial settings, they are also increasingly being incorporated into residential construction. They are used for roofing and facade cladding in homes, offering a combination of insulation and protection for residential buildings. Energy-efficient homes with well-insulated walls and roofs are growing in demand, and sandwich panels provide a practical, cost-effective solution.

7 Benefits of Sandwich Panels:

Sandwich panels are an exceptional choice for a wide variety of building and insulation needs. Here are seven key benefits that make them stand out in the construction industry:

- Excellent Thermal Insulation:

The core material in sandwich panels is designed to offer exceptional thermal insulation, ensuring a comfortable interior environment. By reducing heat loss in winter and heat gain in summer, sandwich panels help maintain the desired temperature within the building. This contributes to a significant reduction in energy consumption, making the structure more energy-efficient and lowering long-term heating and cooling costs.

- Lightweight and Easy to Handle:

In addition to being lightweight, sandwich panels are designed to be easily handled and require minimal lifting equipment, further streamlining the installation process. The reduced weight also means less strain on the building’s foundation, allowing for more efficient use of materials. With quicker installation times, projects can move through various stages faster, improving overall workflow and productivity. The ease of installation makes sandwich panels a preferred choice for both small and large-scale construction projects. Ultimately, their lightweight nature contributes to lower project costs and timely project completion, benefiting contractors and clients alike.

- Fire Resistance:

The fire-resistant properties of sandwich panels not only protect the building structure but also help safeguard sensitive equipment, inventory, and materials within. In industries like food storage, where temperature control is critical, the fire-resistant core material adds an extra layer of protection against fire hazards. Moreover, the fire-resistant sandwich panels contribute to a building’s overall fire rating, which can enhance its insurance premiums and ensure compliance with local fire safety regulations. By preventing the rapid spread of flames, these panels reduce the potential for catastrophic loss and provide a safer environment for workers, visitors, and stakeholders.

- Cost-Effective Solution:

Sandwich panels offer a cost-effective building solution compared to traditional construction materials. The quick installation process, combined with energy-saving properties, makes them an affordable choice for both new builds and refurbishments. Their lightweight design also leads to lower transportation costs, making sandwich panels an economical choice for large-scale construction projects.

- Sound Insulation:

The soundproofing qualities of sandwich panels can be particularly beneficial in spaces where noise control is crucial, such as hospitals, schools, and open-plan offices. By minimizing sound transmission between rooms or from external sources, these panels create a more peaceful and productive environment. In factories and industrial settings, sandwich panels can help reduce noise pollution, improving the comfort and health of workers. Additionally, sandwich panels help in meeting noise reduction standards in certain building codes, making them a practical solution for projects with acoustic requirements. Their ability to control sound contributes to a more comfortable living or working space, enhancing overall well-being.

- Durability and Low Maintenance:

The long-lasting nature of sandwich panels also translates into cost savings over time, as their minimal maintenance requirements reduce ongoing operational costs. Their moisture resistance prevents issues like mould or corrosion, ensuring that the panels remain structurally sound in areas with high humidity or frequent rainfall. Furthermore, the robust exterior shields against physical damage, making sandwich panels ideal for high-traffic areas or sites exposed to harsh environmental factors, such as coastal regions with salt exposure. Their ability to withstand a variety of conditions without significant wear enhances their value as a sustainable and reliable building material.

Environmental Sustainability:

In addition to energy efficiency, the production process for many sandwich panels generates less waste compared to traditional building materials, contributing to a cleaner, more eco-friendly construction process. The reduced need for insulation and additional energy systems also translates into cost savings for building owners and tenants. As sustainable construction becomes increasingly important, sandwich panels offer a viable solution that aligns with green building standards and certifications, such as LEED (Leadership in Energy and Environmental Design). Their lightweight design also reduces the carbon footprint during transportation, making them an environmentally conscious choice from start to finish. Overall, sandwich panels support sustainable development by combining durability, energy efficiency, and recyclability.

Conclusion:

Sandwich panels are an innovative and highly efficient solution for a variety of construction and insulation applications. With their combination of thermal insulation, strength, fire resistance, soundproofing, and environmental sustainability, sandwich panels provide a superior alternative to traditional building materials. Whether used in cold storage, industrial buildings, commercial structures, or residential applications, sandwich panels offer numerous benefits that make them an invaluable tool in the modern construction landscape.

For businesses and individuals looking to take advantage of the versatility and efficiency of sandwich panels, Frigipan provides top-quality sandwich panel solutions tailored to your specific needs. Get in touch with Frigipan today and discover how sandwich panels can enhance the performance, energy efficiency, and safety of your next construction project.